YOUR STRATEGIC PARTNER

Providing tailored plastic manufacturing solutions for all industries.

New Zealand Made

Avid is proudly 100% New Zealand owned and operated

We don’t source product from overseas factories to subsidise our output – everything is manufactured at our Bay of Plenty factory.

When you buy from us you’re buying from a certified ‘Buy New Zealand Made’ company. Wearing the ‘Kiwi’ trademark goes beyond trust and authenticity and speaks to who we are as New Zealanders and how we conduct business here.

Our Vision

Our vision is to lead through innovative solutions

We’re always seeking better ways to improve our processes, utilise recycled & recyclable materials, drive business growth, and enhance sustainability.

As a future-focused company, we’re committed to operating our business with minimal environmental impact.

Partnering with Plastic Bank

In 2022 it was an easy decision for us to partner with Plastic Bank

They offer measurable social, economic & environmental impacts with their range of ethically sourced ocean bound plastics.

We proudly stock their ‘Social Plastic’ range of recycled materials and utilise in projects from food packaging to construction consumables.

Learn more at plasticbank.com

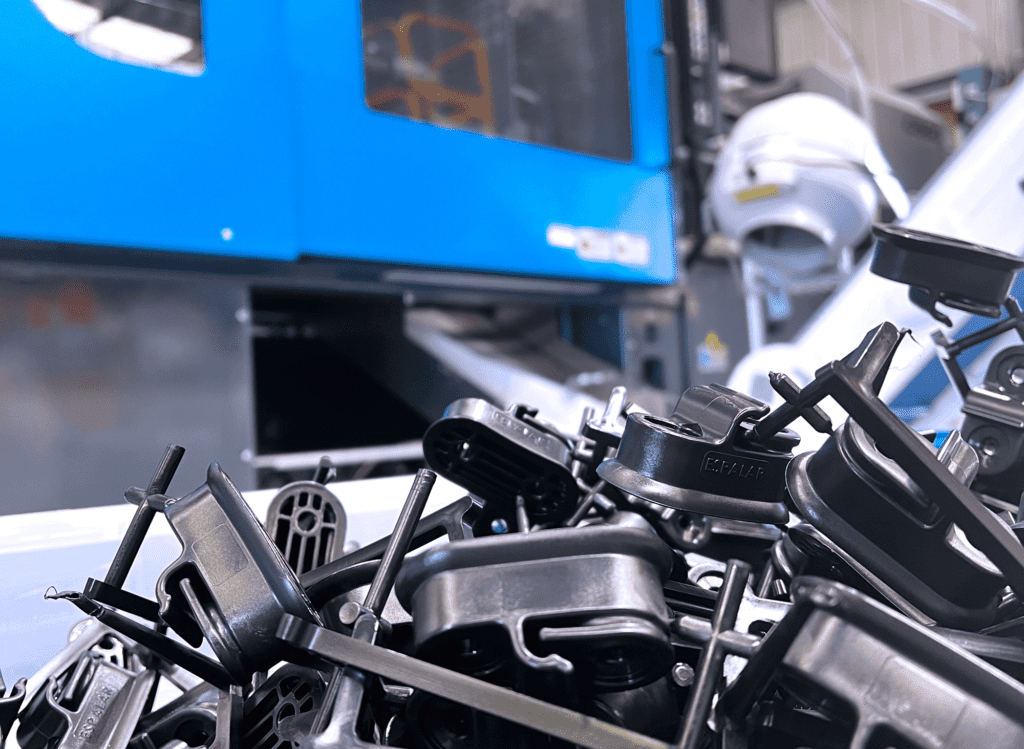

In-house Recycling

Rather than sending our post-industrial waste (faulty and/or reject products) to the landfill we have an in-house, closed loop solution.

We grind the waste into pellet form using an industrial granulator and use this recycled content to manufacture new products.

This internal process gives proof and peace of mind to our clients, and shows that we’re frequently making additions to our manufacturing process to ensure we are conscious and responsible plastic manufacturers.

Innovative Materials

We are focused on staying at the forefront of new material technologies, offering our clients recycled, biodegradable, performance and conventional material options.

100% of FMCG packaging we manufacture is recyclable and we stock a wide range of post-consumer recycled materials, offering an eco-twist for your next project.

FMCG

Medical

Agriculture

Automotive

Construction

Electrical

Design

Every great product starts as a great idea.

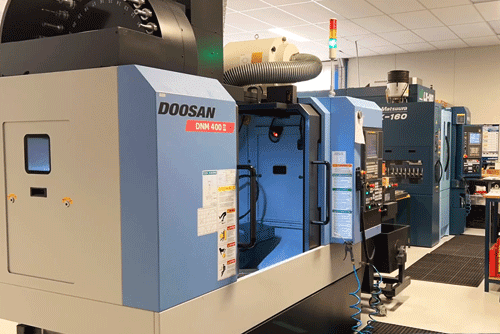

TOOLING

Avid’s engineering facility houses industry leading equipment including CNC machines, surface grinders, lathes, metrology equipment and more.

In-house tool design and toolmaking backed with stringent accuracy, automation and verification processes, ensures…

MOULDING

Talk to the team at Avid to discuss your plastic injection moulding requirements!